Negative pressure fan is a cooling principle that utilizes air convection and negative pressure ventilation. It is a machine that naturally sucks in fresh air from the opposite direction of the installation site (gate or window), quickly forcing hot indoor gases out of the room. Any poor ventilation problem can be improved, and the cooling and ventilation effect can reach 90% -97%.

Product Features:

The negative pressure fan adopts CAD design, which has the characteristics of low investment cost, large air volume, low noise, low energy consumption, stable operation, long service life, and high efficiency; The automatic opening and closing of blinds achieves dustproof, waterproof, and aesthetically pleasing appearance; It can supply air or extract air, making it the best choice for cooling and ventilation in modern workshops. Environmentally friendly and energy-saving negative pressure fans are the mainstream products in the ventilation and cooling equipment market.

Application Introduction

1. Used for ventilation and ventilation: Installed outside the workshop window, usually the lower air outlet is selected to extract odorous gases from the outside. It is commonly used in chemical plants and other applications< Br/>

2. Used in conjunction with a wet curtain: Used for cooling the workshop. In scorching summer, no matter how hot the workshop is, the wet curtain+negative pressure fan system can lower the temperature of your workshop to around 30 ℃ with a certain humidity< Br/>

1. Used for ventilation and ventilation: Installed outside the workshop window, usually the lower air outlet is selected to extract odorous gases from the outside. It is commonly used in chemical plants and other applications< Br/>

2. Used in conjunction with a wet curtain: Used for cooling the workshop. In scorching summer, no matter how hot the workshop is, the wet curtain+negative pressure fan system can lower the temperature of your workshop to around 30 ℃ with a certain humidity< Br/>

3. Applicable scope of negative pressure fan:

(1) Suitable for workshops with high temperatures or odors, such as heat treatment, castings, plastics, aluminum profiles, shoe making, leather parts, electroplating, and various chemical factories< Br/>

(2) Suitable for labor-intensive enterprises such as clothing factories, various assembly workshops, and internet cafes< Br/>

(3) Ventilation and cooling of horticultural greenhouses and livestock farms< Br/>

(4) Especially suitable for places that require cooling and a certain humidity. Such as Cotton mill, wool mills, linen mills, weaving mills, chemical fiber mills, warp knitting mills, texturing mills, knitting mills, silk mills, sock mills and other textile mills< Br/>

(5) Suitable for the field of warehousing and logistics

4. Used as an exhaust fan: Generally, the efficiency of an exhaust fan is relatively poor. A single exhaust fan can blow less than a few people, while a negative pressure fan is not, whether it is used on the ground or hanging in the air. Generally, 4 units are used in a 1000 square meter workshop, which has the effect of wind blowing all over the house< Br/>

Product Advantages

※ Integrating ventilation, ventilation, and cooling< Br/>

※ Energy saving: Low power consumption, only about 10% to 15% of traditional air conditioning< Br/>

※ Environmental protection: CFC free< Br/>

※ Excellent cooling effect: After the external air enters the room through the cooling water curtain, the indoor temperature on the side of the cooling water curtain can reach a cooling effect of 5-10 degrees< Br/>

High investment return rate, with investment costs recoverable within 2 to 3 years< Br/>

Quickly replace and exhaust the turbid, stuffy, and odorous air indoors< Br/>

※ Effectively control the indoor environment, generate different wind speeds in the room, resulting in the cool wind effect, making people feel unusually comfortable and fresh< Br/>

※ Reduce infectious diseases and effectively prevent the large-scale spread of sudden influenza and other viruses. Birds, mosquitoes, and flies are the vectors of infectious diseases. Due to the negative pressure sealed water ventilation system, the probability of vector transmission will be reduced, which will enable staff to work in a comfortable, safe, and reassuring environment.

Installation Notes

&Nbsp& Nbsp& Nbsp& Nbsp& Nbsp& Nbsp& Nbsp; When installing a negative pressure fan, the wall on this side of the fan must be properly sealed. Especially there should be no gaps around the fan. The most ideal method for installing a negative pressure fan is to close all the walls and nearby doors and windows on this side of the fan, and open the doors and windows on the opposite wall of the fan to ensure that the airflow flows in a straight line< Br/>

&Nbsp& Nbsp& Nbsp& Nbsp& Nbsp& Nbsp& Nbsp; The installation of negative pressure fans is a very important project, which has a significant impact on the future use effect of negative pressure fans. It is necessary to pay attention to it at all times throughout the entire installation process< Br/>

Before installation

1) Before installing the negative pressure fan, it is necessary to carefully check whether the negative pressure fan is intact and undamaged, whether the fastening bolts are loose or detached, and whether the impeller collides with the fan cover. Carefully inspect the fan blades or louvers for any deformation or damage during transportation< Br/>

(2) When selecting the air outlet environment for installation, it should be noted that there should be no large obstacles within 2.5-3M of the opposite side of the air outlet< Br/>

During installation

1) Smooth installation: When installing the negative pressure fan, attention should be paid to the horizontal position of the fan and adjust it to a stable level with the foundation plane. The motor must not tilt after installation< Br/>

(2) When installing the negative pressure fan, the adjusting bolts of the motor should be in a convenient position for operation. Adjust the belt tension for ease of use< Br/>

(3) When installing the negative pressure fan bracket, it is necessary to ensure that the bracket is level and stable with the foundation plane. If necessary, angle iron should be installed next to the negative pressure fan for reinforcement< Br/>

(4) After the installation of the negative pressure fan, the sealing around it should be checked. If there are gaps, they can be sealed with a solar panel or glass adhesive< Br/>

3. After installation

(1) After installation, check if there are any remaining tools and debris inside the negative pressure fan. Use your hand or lever to move the fan blades and check for any signs of tightness or friction, as well as any items that hinder rotation. Only then can you proceed with the test run< Br/>

(2) If there is vibration of the negative pressure fan or abnormal sound of "buzzing" or other abnormal phenomena in the motor during operation, the machine should be shut down for inspection. It should be repaired before starting up for use< Br/>

Maintenance of negative pressure fan

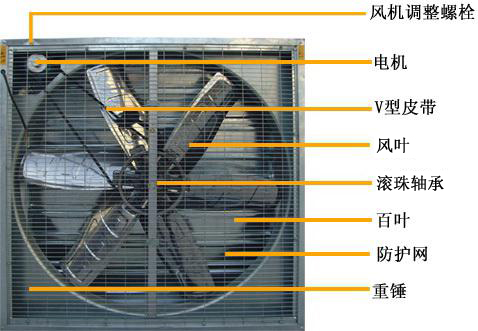

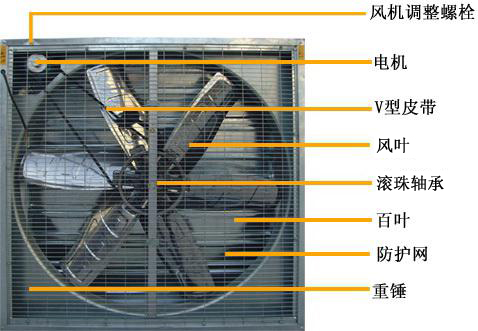

1. The structure of negative pressure fans is divided into: fan adjustment bolts, motors, U-belts, fan blades, flow ball bearings, louvers, protective nets, heavy hammers and other accessories< Br/>

2. Daily maintenance of negative pressure fan:

(1) Clean up impurities from the protective net,

(2) Check the looseness of the belt, and if any looseness is found, immediately arrange for adjustment and resetting< Br/>

(3) Is there any abnormal noise in the bearings of the motor? If so, check if there is still lubricating oil on the motor< Br/>

3. Regarding the maintenance and upkeep of the motor, we can start from the following aspects:

(1) Firstly, disconnect the power supply of the host and check if the ground wire is well grounded< Br/>

(2) Check if the screws and coupling of each part are tightened

(3) Check whether the insulation resistance of the motor meets the regulations and check the main circuit contacts according to the instructions. If the contact is severely burned or worn, it should be replaced immediately< Br/>

4. For the maintenance of the air valve, the following aspects can be considered:

(1) Adjust the tightness of the belt, rotate the wind wheel by hand, and observe if the rotation is smooth< Br/>

(2) Check and replace the gaskets and sealing fillers between each joint surface< Br/>

(3) Clean the motor rotor, filter, and inside the casing. To prevent rusting, the paint peeling parts should be promptly repainted< Br/>

(4) To ensure the flexibility and stability of the coupling and bearings, lubricating oil should be added to the rotating parts< Br/>

5. For the maintenance and repair of electrical circuits, the following points should be noted:

(1) Check whether the mechanical opening and closing actions of the regulating valve are flexible and reliable, and whether the opening and closing angle signs are clear and visible< Br/>

(2) Whether the indicator, Voltmeter and Ammeter are normal. Whether all parts of the fan operate differently and whether the three-phase current value is balanced. 3. Check whether the components inside the control box of each remote control point are normal< Br/>

6. Perform continuous start and stop operations and check if the remote control at each point is correct and reliable< Br/>

7. Test run for two hours, observe whether the temperature of the motor bearing and the temperature rise of the motor are within the normal range

return

return